Sediment removal & dewatering

We offer a complete concept for emptying and dewatering the sediment.

Sediment discharge and dewatering

Sediment, also known as silt, is larger and heavier particles that accumulate on the bottom as the water is treated. In order for a treatment pond to continue to function well and have a good treatment effect, the pond must be emptied of sediment. Tecomatic, together with our partner Clear Dredge, offers a complete concept for emptying and dewatering the sediment.

We help you if you have problems with

- Eutrophication

- Smell

- Clogged pumping stations due to too much sediment

Powerful and effective concept

Sedimentation occurs when water is allowed to pass through a confined pool of water that is built cost-effectively with Tecomatic floating walls. When the current becomes non-existent, accompanying particles sink to the bottom where they can be collected. Our sediment discharge concept is based on a powerful pumping method that is well suited for dredging ponds, controlled water environments and for emptying sedimentation ponds. The pond is emptied of sediment and dewatered directly on site. The end product is a dry, fine pulp and a dam that has its function and capacity restored.

The work is carried out using specially built suction pontoons designed to empty sedimentation ponds. These allow us to pump the sediment out of the dam in a controlled manner while the plant continues to operate, without having to empty the water level.

An effective method to reduce particle-bound phosphorus, heavy metals and BOD content in water bodies.

Dissolved substances cannot be purified unless chemical substances are added to cause them to precipitate. Examples of chemical substances that can be added are iron chloride and aluminum salts.

Process of emptying and cleaning of sediments

A manned electric pontoon sucks up sediment from the bottom. The operation and water level of the dam is not affected.

The sediment is pumped via a hose to a polymer station where dewatering chemicals are added. Flocculation of particles begins while the sediment is pumped to a geotube.

The nature of the remaining sediment and the level of contamination will determine the appropriate disposal. For example, in some cases it can be used as a soil amendment.

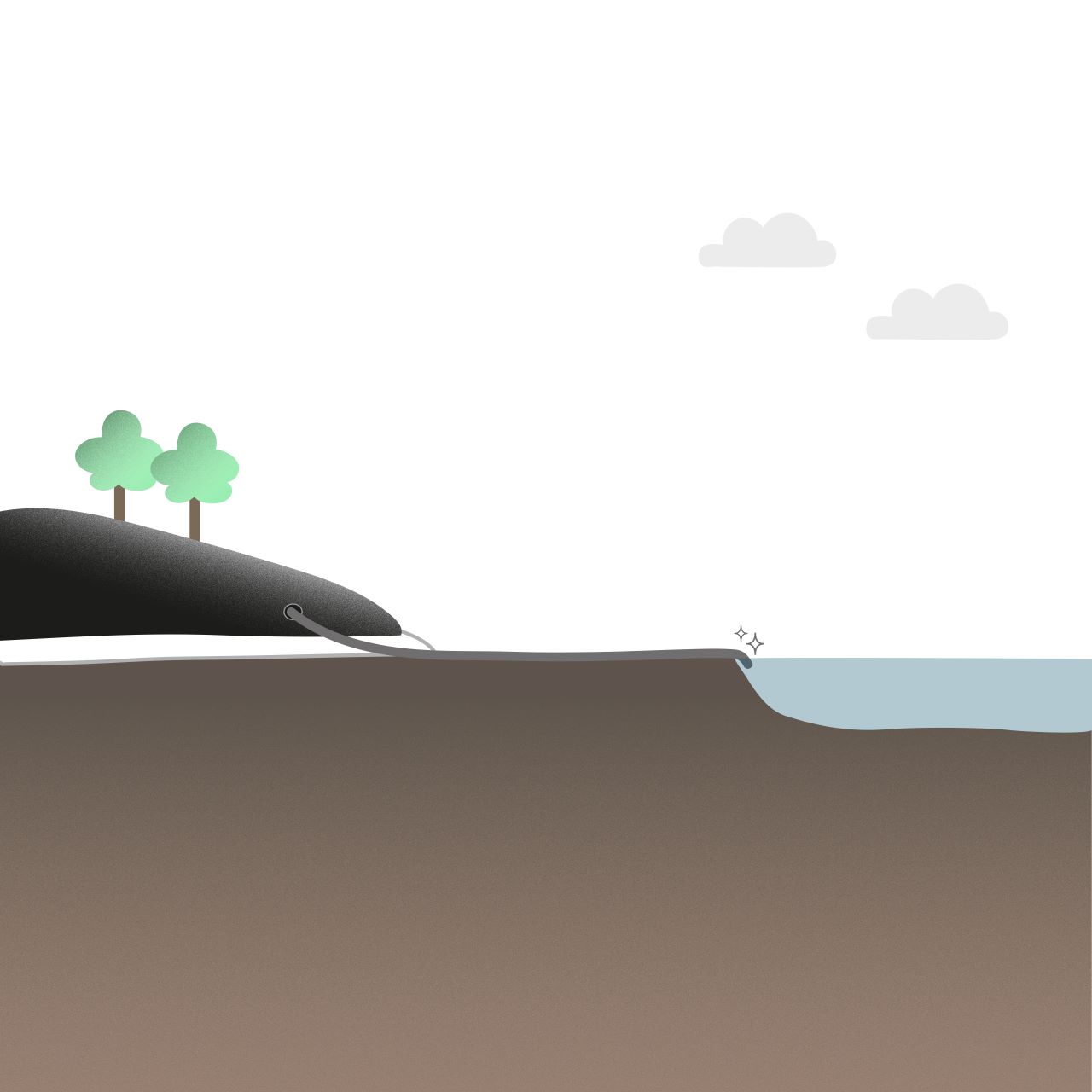

Low flow dredging process

Tecomatic also offers low flow dredging, a method that is gentle on the bottom fauna and aquatic organisms as only the top layers of sediment are sucked up. This is particularly important in environments where we want to minimize turbidity and avoid disturbing marine life.

A manned electric pontoon sucks up sediment from the bottom. The operation and water level of the dam is not affected.

The sediment is pumped via a hose up to a control station where polymer is added. The sediment is then pumped to a geotube.

The sediment is dewatered in the geotube and the reject water is pumped to a sand filter container. The sand filter purifies the water from smaller particles and returns to the lake as clean water.

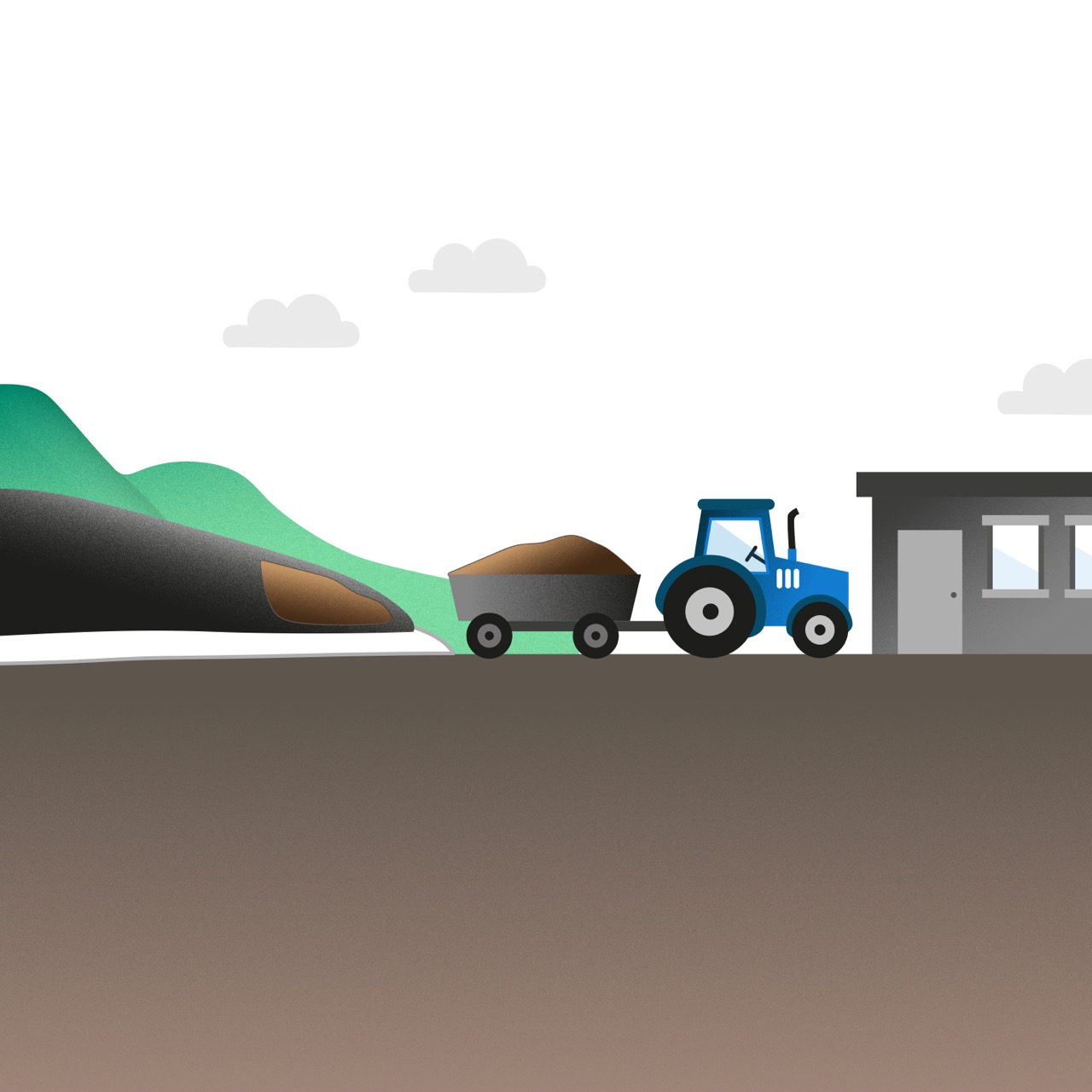

What remains in the geotube are nutrient-rich sediments that contain, among other things, phosphorus. These can be used as fertilizer in agriculture.

Contact us today

Our technical sales representatives and product specialists will help you find the best solution for your project.